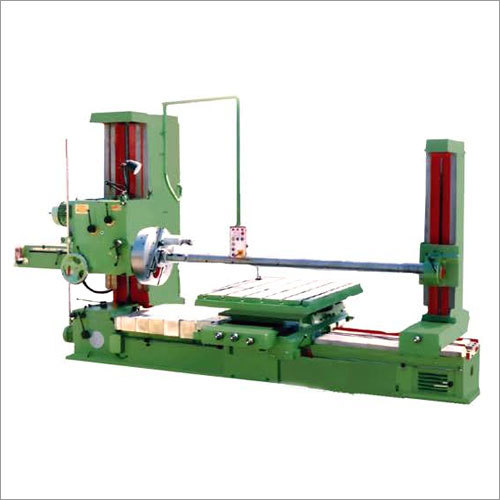

Floor Boring Machine

Floor Boring Machine Specification

- Noise Level

- Below 85 dB(A)

- Table Size

- 1250 x 1400 mm

- Machine Type

- Horizontal Floor Boring Machine

- Dimension (L*W*H)

- 4500 x 3000 x 2200 mm

- Cutting Area

- 1000 x 1000 mm (typical)

- Motor Power

- 7.5 kW Main Motor

- Condition

- New

- Diameter

- Max spindle diameter 100 mm

- Spindle Speed

- 35 - 1150 RPM (variable speed)

- Features

- Heavy-duty construction, precision spindle bearings, large worktable, robust design

- Frequency

- 50 Hz

- Product Type

- Floor Boring Machine

- Material

- Cast Iron Structure

- Computerized

- Yes, optional

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- Conventional/Manual as standard, CNC Optional

- Control System

- Manual/CNC (if configured)

- Voltage

- 415V, 50Hz (Standard for industrial machines)

- Power

- 7.5 kW

- Power Source

- Electric

- Weight (kg)

- Approx. 5000-9000 kg (depends on model)

- Capacity

- Max boring diameter 1000 mm (varies by configuration)

- Color

- Industrial Blue/Grey

- Usage & Applications

- Heavy-duty boring, milling, drilling operations for large components

- Lubrication System

- Automatic centralized lubrication

- Bed Type

- Box type, ribbed for rigidity

- Vertical Travel (Y Axis)

- 1600 mm

- Spindle Travel

- 900 mm

- Table Load Capacity

- Up to 6 Tons

- Spindle Taper

- ISO 50

- Coolant System

- Fitted, continuous flow

- Work Table Traverse

- 1800 mm (X Axis)

- Installation Required

- Yes, with leveling and foundation

- Longitudinal Travel (Z Axis)

- 2200 mm

Floor Boring Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Floor Boring Machine

Floor Boring Machine provided by us, is widely used for shaping the larger components. This machine is mainly used to bore horizontal holes into workpieces. This machine is tested under different parameters to ensure its high quality. This machine is used in heavy industry and also for building turbines and generators. Floor Boring Machine has high installation, simple operation, low maintenance and very cost effective in nature. This machine can be easily availed at nominal rates, by our valued customers.

Engineered for Precision and Durability

Built with an all-cast iron, ribbed box bed for maximum rigidity, this floor boring machine guarantees precise machining and sustained stability during heavy-duty operations. The automatic lubrication system and robust spindle bearings further enhance reliability for demanding workshop environments.

Versatility in Industrial Applications

Designed for versatility, the machine handles boring, milling, and drilling of large workpieces across various industries. Its generous spindle and work table ranges accommodate complex components, while optional CNC upgrades offer advanced automation for streamlined workflows.

Seamless Installation and Support

Installation is completed with professional leveling and custom foundation preparation, ensuring operational precision from the outset. Supported by distributors and manufacturers across India, users receive prompt technical guidance, after-sales support, and application training as needed.

FAQ's of Floor Boring Machine:

Q: How is the Floor Boring Machine installed and what preparations are needed?

A: Installation requires professional leveling and a dedicated foundation to support the machine's weight and ensure proper operation. Our team or authorized technician will guide you through the process, including requirements for space and power connection (415V, 50 Hz).Q: What are the main benefits of using this Floor Boring Machine in heavy-duty applications?

A: The machine delivers high precision and durability due to its rigid box-type cast iron bed, automatic lubrication, and precise spindle bearings. It can process large workpieces up to 6 tons, ensuring productivity and machining accuracy for industrial components.Q: When should I consider upgrading to the CNC configuration for this machine?

A: Upgrade to the CNC configuration when your production requires repeatable, complex part geometries, and enhanced automation. CNC offers improved process consistency, shorter cycle times, and easier program management for batch production.Q: Where is this Floor Boring Machine typically used in industry?

A: This machine is commonly found in manufacturing facilities, fabrication shops, power plants, and heavy equipment industries where precision boring, milling, or drilling of large, heavy parts is required.Q: What is the process for operating the machine-manual or computerized?

A: The standard machine is operated manually using conventional controls. However, a computerized (CNC) system is available as an option, allowing for programmable control, increased automation, and repeatability according to the user's needs.Q: How does the coolant and lubrication system benefit daily operation?

A: The fitted continuous flow coolant system prevents overheating during intense operations, while the automatic centralized lubrication extends the lifespan of critical components, reduces maintenance intervals, and supports consistent performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Boring Machine Category

Boring Machine

Price 2000000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Voltage : 220240 Volt (v)

Power Source : Electric

Computerized : No

Vertical Boring Machine

Price 900000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : MS

Voltage : 220240 Volt (v)

Power Source : Electric

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free