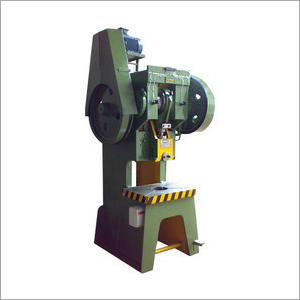

H Type Power Press

H Type Power Press Specification

- Material

- Mild Steel (MS) frame, high-grade steel components

- Power

- 10 Ton to 200 Ton (varies by model)

- Voltage

- 380V / 415V AC, 3 Phase, 50 Hz

- Dimension (L*W*H)

- 1900 mm x 900 mm x 2500 mm (approx, varies by capacity)

- Application

- Sheet metal forming, punching, blanking, pressing operations

- Accessories

- Motor, Flywheel, Clutch, Die, Electric Panel, Lubrication System

- Frame Type

- Rigid welded H-frame construction

- Throat Depth

- 150 mm to 400 mm

- Slide Adjustment

- 50 mm to 120 mm

- Stroke Length

- 75 mm to 250 mm (depends on model)

- Control Panel

- Semi-automatic and manual modes available

- Strokes Per Minute

- 30 to 55 SPM

- Bed Size

- 700 mm x 400 mm to 1600 mm x 1000 mm (varies by model)

- Surface Finish

- Anti-corrosive painted

- Safety Features

- Mechanical overload protection, two-hand operation, safety guard

- Shut Height

- 300 mm to 500 mm

- Ram Adjustment

- Variable with hand wheel

H Type Power Press Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About H Type Power Press

H Type Power Press is a power press manufactured in H shape with two pillars firmly grounded to apply intense press. In general, a power press is used for cutting and pressing materials particularly different grades of steel and stainless steel. The cutting is part of the process involved in the fabrication of different types of machines, equipment or fabricated stuffs. The H Type Power Press, with its two heavy pillars, is able to exert more force for punching and cutting metallic sheet to be used in aeronautical, automobile and spacecraft industries.

Specification

| Capacity in Tons | 10 | 20 | 30 | 50 | 75 | 100 | 150 | 200 | 250 | 300 |

| Bed Size | 280x330 | 330x406 | 381x431 | 457x508 | 560x560 | 585x635 | 685x735 | 785x810 | 865x915 | 915x1015 |

| Bed to Ram Bottom | 200 | 228 | 275 | 305 | 330 | 380 | 455 | 508 | 550 | 600 |

| Stroke Length | 50 | 55 | 63 | 80 | 90 | 100 | 145 | 150 | 150 | 175 |

| Crank Shaft Dia out of | 75 | 80 | 100 | 110 | 130 | 156 | 170 | 205 | 230 | 256 |

| Gear Dia | 430 | 560 | 610 | 660 | 765 | 865 | 965 | 1066 | 1170 | 1220 |

| Fly Wheel Dia | 540 | 570 | 685 | 765 | 835 | 965 | 1095 | 1200 | 1320 | 1420 |

| Hole in Ram for Die Clamping | 25.4 | 31.75 | 31.75 | 38.1 | 44.45 | 50.8 | 50.8 | 63.5 | 76.2 | 76.2 |

| Floor to Top of Bed | 735 | 735 | 735 | 735 | 735 | 735 | 735 | 735 | 735 | 735 |

| No. of Strokes per minute | 65 | 60 | 60 | 50 | 45 | 35 | 30 | 30 | 250 | 22 |

| Overall Height without Motor | 1520 | 1765 | 1790 | 2000 | 2160 | 2340 | 2540 | 2900 | 3160 | 3430 |

| Approx. Floor Area Required | 762x635 | 762x686 | 838x686 | 1016x762 | 1016x762 | 1067x863 | 1600x1040 | 1600x1140 | 1750x1220 | 1900x1270 |

| Power Required (1440 RPM) | 2H.P | 2H.P | 3H.P | 5H.P | 7.5H.P | 10H.P | 15H.P | 20H.P | 25H.P | 30H.P |

Rigid H-Frame Construction for Maximum Stability

The H Type Power Press features a robust H-frame structure that enhances stability while minimizing deflection during heavy operations. This design ensures consistent results, even under demanding loads, and prolongs the machine's operational life. Crafted from premium mild steel, the press offers reliability for intensive forming, punching, and pressing tasks.

Tailored Flexibility and Precision

With bed sizes and stroke lengths varying by model, users can select the press that matches their specific application, from delicate sheet metal tasks to heavy-duty blanking. Variable slide adjustment and customizable shut height contribute to precise alignment and accuracy. An integrated hand wheel allows for straightforward ram adjustments.

Advanced Safety and User-friendly Controls

Operator safety is a priority, featuring mechanical overload protection, two-hand operation, and safety guards. The control panel supports both semi-automatic and manual modes, catering to different workflow requirements while maintaining ease of operation. These features enhance productivity while adhering to stringent safety standards.

FAQ's of H Type Power Press:

Q: How is the bed size selected for different models of the H Type Power Press?

A: The bed size of the H Type Power Press ranges from 700 mm x 400 mm to 1600 mm x 1000 mm, allowing selection based on the specific size and type of metalwork required. Larger beds accommodate larger workpieces or multiple dies, making the press adaptable to various industrial tasks.Q: What safety mechanisms are included to protect the operator during use?

A: Safety features include mechanical overload protection to prevent damage, two-hand operation to ensure hands are clear during pressing, and a robust safety guard. These measures significantly reduce the risk of workplace accidents and equipment damage.Q: When should you adjust the slide and how is it accomplished?

A: Slide adjustment should be made whenever a change in die or material thickness occurs, or to meet the stroke requirements for specific tasks. The press provides slide adjustments ranging from 50 mm to 120 mm, typically performed via a dedicated hand wheel for fine-tuning.Q: Where can the H Type Power Press be used effectively?

A: This power press is ideal for use in fabrication workshops, industrial manufacturing units, and sheet metal processing facilities across India. Its robust build and adaptable specifications suit a broad range of metal forming, punching, blanking, and pressing applications.Q: What is the process for switching between manual and semi-automatic modes?

A: Switching operating modes is handled through the control panel. Operators can select manual mode for increased control during setup or precision work, or semi-automatic mode for repeated cycles in high-volume production, thereby enhancing efficiency and versatility.Q: How does the H-frame design benefit production quality?

A: The rigid H-frame construction minimizes frame deflection and vibration, ensuring uniform force distribution during pressing operations. This translates into improved precision, consistent part quality, and extended machine life, particularly in high-tonnage and repetitive operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Power Press Category

C Type Power Press

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power Press Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS