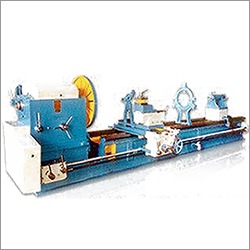

Heavy Duty Roll Turning Lathe Machine

Heavy Duty Roll Turning Lathe Machine Specification

- Product Type

- Heavy Duty Roll Turning Lathe Machine

- Material

- Cast Iron Body, High-Grade Alloy Steel Components

- Cutting Thickness

- Up to 200 mm (depending on material and tool)

- Cutting Speed

- Up to 400 RPM (variable as per model)

- CNC Or Not

- Conventional (Manual Control)

- Automatic Grade

- Semi-Automatic

- Control System

- Manual/Hand Wheel Control

- Max. Swing Diameter

- 1100 mm

- Voltage

- 415 V, 3 Phase, 50 Hz

- Weight (kg)

- Approx. 9500 kg

- Dimension (L*W*H)

- 5400 mm x 1700 mm x 1400 mm (approx)

- Capacity

- Up to 40 Tons Roll Weight

- Feature

- Heavy Duty Construction, Precision Ground Bed, Hardened Gears, Steady Rest Provision

- Color

- Industrial Grey & Yellow

- Lead Screw Diameter

- 50 mm

- Center Height

- 550 mm

- Spindle Bore

- 150 mm

- Distance Between Centers

- 4000 mm

- Bed Length

- 5200 mm

- Tailstock Travel

- 300 mm

- Feed Range

- 0.05 to 5 mm/rev

- Surface Finish

- Fine Machined

- Tool Post Type

- 4-Way Tool Post

- Lubrication System

- Centralized Automatic Lubrication

- Chuck Size

- 800 mm (4 jaw chuck)

- Headstock Type

- All Gear Headstock

- Application

- Roll Turning, Heavy Metal Machining

- Main Motor Power

- 12.5 HP

- Noise Level

- Below 80 dB

Heavy Duty Roll Turning Lathe Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Heavy Duty Roll Turning Lathe Machine

Robust Construction and High Capacity

Built for demanding industrial environments, this lathe features a heavy-duty cast iron body and precision ground bed, ensuring stability and longevity. With a maximum roll weight capacity of 40 tons and a swing diameter of 1100 mm, it effortlessly handles large and heavy workpieces, making it ideal for roll turning and heavy metal machining tasks.

Precision and Efficient Operation

Equipped with hardened gears and a 4-way tool post, this machine guarantees precise cuts and efficient tool handling. The variable feed range from 0.05 to 5 mm/rev and a cutting thickness up to 200 mm allow for versatile applications, while the centralized automatic lubrication system ensures smooth operation and reduced maintenance.

FAQ's of Heavy Duty Roll Turning Lathe Machine:

Q: How does the all gear headstock benefit the operation of this roll turning lathe?

A: The all gear headstock provides enhanced torque and consistent power transmission, which is vital for heavy-duty and precise roll turning applications. This ensures smoother operation, especially when handling large or heavy workpieces.Q: What is the maximum workpiece size this machine can accommodate?

A: The lathe accommodates workpieces with a maximum swing diameter of 1100 mm, a bed length of 5200 mm, and a distance between centers of 4000 mm, making it suitable for substantial industrial rolls and shafts.Q: When should the centralized lubrication system be used or maintained?

A: The centralized automatic lubrication system operates continuously during machine use, automatically supplying lubrication to critical components. Regular monitoring of the lubricant levels and periodic inspection as part of scheduled maintenance is recommended to ensure optimal performance.Q: Where can this heavy-duty roll turning lathe be installed?

A: This machine is suitable for installation in heavy engineering workshops, steel plants, and manufacturing units across India, especially where robust roll turning or heavy metal machining is required.Q: What is the process for changing the feed rate or cutting speed on this machine?

A: The feed rate can be adjusted between 0.05 to 5 mm/rev using manual controls, and the cutting speed (up to 400 RPM) is variable according to the specific model, allowing operators flexibility in machining diverse materials and profiles.Q: How does the machine ensure operator safety and low noise levels?

A: Operator safety is enhanced through features like the steady rest provision and manual control system, while advanced engineering and construction keep noise levels below 80 dB, creating a safer, quieter working environment.Q: What are the main benefits of using this lathe for roll turning?

A: Benefits include high load capacity, precise machining with fine surface finishes, durable construction, and reliable performance for heavy-duty applications, making it an essential asset for roll manufacturing and metal machining industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machine Category

Extra Heavy Duty All Geared Roller Grooving Lathe Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V, 3 Phase, 50 Hz

Product Type : Other, All Geared Roller Grooving Lathe Machine

Max. Swing Diameter : 900 mm

Cutting Speed : Variable, up to 1200 RPM

Industrial Heavy Duty Lathe Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415V, 50Hz, 3 Phase

Product Type : Other, Heavy Duty Lathe Machine

Max. Swing Diameter : 800 mm

Cutting Speed : 251500 RPM (Variable)

Roll Turning Lathe Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V, 3 Phase, 50 Hz

Product Type : Other, Roll Turning Lathe Machine

Max. Swing Diameter : Up to 1500 mm

Cutting Speed : Up to 500 mm per min

Medium Duty Lathe Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free