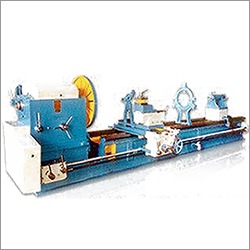

Industrial Light Duty Lathe Machine

Industrial Light Duty Lathe Machine Specification

- Product Type

- Industrial Light Duty Lathe Machine

- Material

- Cast Iron

- Cutting Thickness

- Up to 20 mm

- Cutting Speed

- 35-600 rpm (variable)

- Engraving Area

- 350 mm

- CNC Or Not

- No

- Automatic Grade

- Manual

- Control System

- Manual Control

- Max. Swing Diameter

- 400 mm

- Voltage

- 415 V (Three Phase)

- Weight (kg)

- 650 kg

- Dimension (L*W*H)

- 1700 x 700 x 1130 mm

- Capacity

- Light Duty Turning

- Feature

- High Accuracy, Rigid Construction, Easy Operation

- Color

- Green

- Carriage Movement

- Smooth sliding

- Coolant System

- Provision available

- Lead Screw Diameter

- 25 mm

- Surface Finish

- Polished

- Motor Power

- 2 HP

- Tool Post Type

- Four-way

- Bed Length

- 4 Feet

- Spindle Bore

- 38 mm

- Application

- Metal Turning, Facing, Thread Cutting

- Distance Between Centers

- 700 mm

- Drive Type

- Geared Head

- Chuck Size

- 200 mm

- Tailstock Quill Travel

- 100 mm

- Spindle Speed Range

- 6 speeds

Industrial Light Duty Lathe Machine Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Industrial Light Duty Lathe Machine

Engineered for Precision and Reliability

Built with a solid cast iron construction and a polished bed, this light duty lathe provides exceptional strength and dimensional stability. Its geared head drive and smooth sliding carriage support highly accurate machining, ensuring users achieve fine finishes on every project. The 2 HP motor delivers reliable power, suitable for light industrial applications.

User-Friendly Operation and Maintenance

Featuring a manual control system and a four-way tool post, this lathe is designed for effortless use by both new and experienced operators. All key controls are conveniently located, and the provision for a coolant system keeps operations clean and efficient. With easy maintenance and robust engineering, downtime is minimized.

Versatile Applications in Metalworking

This lathe machine is well-suited for a variety of applications, including turning, facing, thread cutting, and engraving up to 350 mm. Its variable speed settings and adjustable components enable operators to work with different metals and achieve the required surface finish for both functional and decorative parts.

FAQ's of Industrial Light Duty Lathe Machine:

Q: How do I install and set up the 4-feet Industrial Light Duty Lathe Machine?

A: Installation should be carried out on a level, stable floor, using standard lifting equipment due to the machine's 650 kg weight. Electrical connections must match the 415 V three-phase requirement. After leveling the bed, secure the machine and ensure the spindle, carriage, and tailstock move freely before operation.Q: What types of materials are suitable for machining with this lathe machine?

A: This lathe is designed for light-duty turning and works best with materials such as mild steel, aluminum, brass, and certain plastics. Its robust cast iron structure and geared head drive facilitate high-accuracy operations on these metals.Q: When should the coolant system be used during machining?

A: Engage the coolant system whenever prolonged operations or high cutting speeds are expected, particularly with harder metals or when fine surface finishes are required. This helps reduce tool wear, maintain surface quality, and prevent excessive heat build-up.Q: Where can this lathe machine be applied most effectively?

A: The lathe is ideal for small to medium-sized workshops, tool rooms, training institutes, and light manufacturing units in India that need accurate turning, facing, threading, and basic engraving on light metal parts.Q: What is the process for changing spindle speeds on this machine?

A: To change spindle speeds, stop the spindle, disengage power, and select one of the six available speed settings via the gear head levers. Always ensure correct alignment before re-engaging the drive to prevent mesh wear or loss of accuracy.Q: How do I utilize the four-way tool post for efficient operations?

A: The four-way tool post allows you to mount up to four cutting tools at once, reducing tool changeover time. Simply rotate the post to switch between tools and lock in place, enabling uninterrupted operations during complex turning or threading tasks.Q: What are the key benefits of choosing this manual lathe machine for my workshop?

A: The main advantages include high accuracy, easy operation, low maintenance, and robust construction. Its light duty design is perfect for precise work, training purposes, and producing small batches with consistent quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machine Category

Facing Lathe Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue/Grey

Product Type : Other, Facing Lathe Machine

Voltage : 415 V

Feature : Other, Robust Construction, High Precision

Industrial Heavy Duty Lathe Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue & White

Product Type : Other, Heavy Duty Lathe Machine

Voltage : 415V, 50Hz, 3 Phase

Feature : Other, Robust Construction, Precision Engineering, Long Life, High Efficiency

V Belt Lathe Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Green (Industrial Standard)

Product Type : Other, V Belt Lathe Machine

Voltage : 220V 440V, 3 Phase

Feature : Other, Heavy duty construction, smooth operation, adjustable speeds

Semi Gear Head Lathe Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Grey and Blue

Product Type : Other, Semi Gear Head Lathe Machine

Voltage : 415 V

Feature : Other, High Precision, Rigid Construction

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS