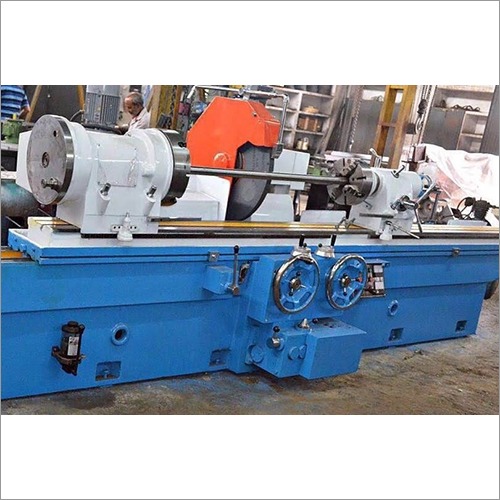

Roll Grinding Machine

MOQ : 1 Piece

Roll Grinding Machine Specification

- Production Capacity

- Up to 12 rolls/shift

- Noise Level

- Low, <75 dB

- Features

- High precision, Robust construction, User-friendly interface

- Machine Type

- Roll Grinding

- Drive

- Direct & Belt Driven as per model

- Model No

- RGM-3500

- Motor Power

- Main motor 20-30 HP

- Cooling System

- Water Cooled

- Connectivity Options

- HMI Touch panel, optional remote monitoring

- Frame Type

- Heavy rigid bed

- Frequency

- 50 Hz

- Lubricating System

- Centralized Lubrication

- Power Rating

- 30 HP

- Control System

- PLC Based

- Voltage

- 380-440 V

- Accuracy

- 0.001 mm

- Operating Temperature

- 5C to 45C

- Product Type

- Roll Grinding Machine

- Technology

- CNC/Conventional

- Power Source

- Electric

- Operating Type

- Automatic/Semi-Automatic

- Power

- 15-30 kW

- Pressure

- Adjustable, as per application

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- 5200 x 1800 x 1600 mm (approx)

- Weight (kg)

- 7500 kg (approx)

- Color

- Industrial Grey & Blue

- Usage & Applications

- Grinding and finishing of industrial rolls in steel, paper, textile industries

- Max Roll Weight Load

- 3000 kg

- Wheel Material

- Corundum/Aluminium Oxide

- Roll Length Capacity

- 500 mm to 3000 mm

- Wheel Size

- 500 mm x 50 mm x 203 mm

- Coolant Capacity

- 100 L

- Table Traverse Speed

- Variable, up to 12 m/min

- Installation Service

- Available upon request

- Roll Diameter Range

- 100 mm to 900 mm

- Safety Features

- Emergency stop, Interlocks, Splash guards

- Grinding Wheel Speed

- 1440 RPM

- Hydraulic System

- Integrated for table movement and headstock

- Spindle Speed

- Upto 900 RPM

Roll Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Roll Grinding Machine

Roll Grinding Machine is a heavy-duty industrial machine that is popularly known among our customers owing to its superior design and performance. The grinding machine is designed and developed in our state of the art production division with the help of cutting-edge tools and techniques. The grinding machine is easy to use and maintain. It has got rugged construction and capability of standing impacts, rust, and tough atmospheric conditions, therefore, the machine is sure to last for an extended period of time. Our customers can approach us to purchase the Roll Grinding Machine at a budget-friendly price.

Advanced Grinding Technology

Benefit from state-of-the-art CNC/conventional control systems and a versatile HMI touch panel, which enable precise roll finishing and easy customization. Variable table speeds and direct or belt-driven configurations suit diverse production demands.

Robust Construction and High Capacity

The RGM-3500 offers a heavy, paint-coated frame for stability and durability. With the capability to process rolls up to 3000 kg and deliver up to 12 rolls per shift, this machine is ideal for high-volume industrial environments.

Integrated Safety and Efficiency

Operators enjoy confidence with emergency stop mechanisms, interlocks, splash guards, and low noise levels. Centralized lubrication and adjustable hydraulic systems simplify maintenance and uphold consistent performance.

FAQ's of Roll Grinding Machine:

Q: How does the Roll Grinding Machine ensure high precision during operation?

A: The machine features a rigid frame, PLC-based control, high-precision spindle, and HMI interface, achieving an accuracy of 0.001 mm even under heavy loads. CNC options further optimize precision for demanding grinding and finishing tasks.Q: What types of rolls can be processed with this machine, and in which industries is it commonly used?

A: Rolls with diameters from 100 mm to 900 mm and lengths between 500 mm and 3000 mm are suitable. Industries such as steel, paper, and textiles frequently use this machine for their grinding and surface finishing requirements.Q: When is installation service available, and what does it include?

A: Installation service is available upon request for customers across India. It includes on-site machine setup, calibration, and operator training to ensure seamless integration and optimal performance from the start.Q: Where can this machine be installed, and what are its space requirements?

A: The machine is designed for industrial plants with adequate space to accommodate its dimensions (approximately 5200 x 1800 x 1600 mm). It serves as a durable centerpiece for roll grinding operations in production facilities.Q: What is the process and usage for grinding with this machine?

A: Operators use the automated or semi-automatic system to position the roll, set grinding parameters via a user-friendly interface, and activate the controlled movement and cooling systems. The process delivers high-quality surfaces and consistent results for each roll.Q: How does the machine's safety system benefit operational reliability?

A: Safety is prioritized with emergency stops, interlocks, splash guards, and adjustable pressure controls. These features protect operators and machinery, minimizing downtime and ensuring a secure workplace.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Grinder Machine Category

Industrial Roll Grinding Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Industrial Grey

Cooling System : WaterCooled

Power : 15 kW

Usage & Applications : Industrial Roll Grinding for Paper, Steel, Textile, Rubber & Printing Industries

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free