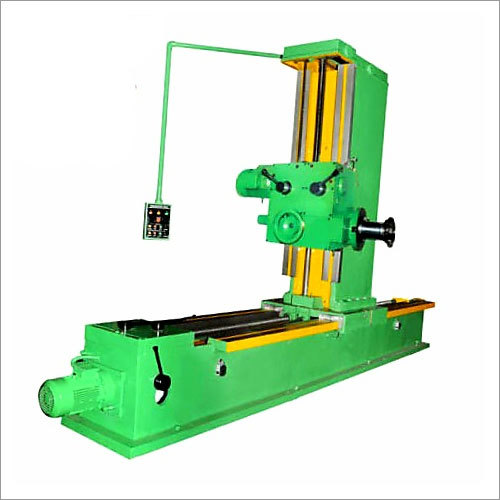

End Milling and Facing Machine

End Milling and Facing Machine Specification

- Drive

- V-Belt

- Control System

- Manual Handwheel & Electrical Panel

- Frequency

- 50 Hz

- Production Capacity

- 50 Units/Month

- Operating Temperature

- 5C to 40C

- Machine Type

- End Milling, Facing

- Voltage

- 220-240V

- Noise Level

- < 72 dB

- Features

- Rugged Construction, Quick Setting, High Precision

- Frame Type

- Heavy Duty Steel Frame

- Cooling System

- Integrated Coolant Tank

- Model No

- EMFM-1150

- Motor Power

- 2 HP

- Lubricating System

- Manual Lubrication

- Accuracy

- 0.02 mm

- Power Rating

- 2 HP

- Product Type

- End Milling and Facing Machine

- Technology

- Conventional Machining

- Power Source

- Electric

- Operating Type

- Semi-Automatic

- Power

- 2 HP

- Pressure

- Hydraulic - Up to 80 bar

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 1150 x 700 x 1450 mm

- Weight (kg)

- 225 kg

- Color

- Blue & Silver

- Usage & Applications

- Aluminum Profile End Milling, Facing operations

- Standard Accessories

- Tool Kit, Work Clamp, Manual

- Travel Length (X/Y/Z)

- 250/130/150 mm

- Packing Type

- Wooden Box

- Tool Changing

- Manual

- Application Material

- Aluminum, PVC, Light Alloys

- Maximum Cutter Diameter

- Diameter up to 160 mm

- Main Shaft Speed

- 2800 RPM

- Table Size

- 500 x 220 mm

- Tool Holder Type

- ISO 40

- Spindle Diameter

- 40 mm

- Clamping Capacity

- Up to 160 mm profile width

- Coolant Capacity

- 15 litres

- Safety Features

- Overload Protection, Emergency Stop

End Milling and Facing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About End Milling and Facing Machine

End Milling and Facing Machine is a high performance multipurpose machining unit which is used for the cutting and finishing of various types of engineering grade metallic and alloyed components to make unique designs and cuts with higher precision and accuracy. It is provided with high performance electrical motor which is responsible for the smooth and controlled functioning of the mechanical components fixed within the mechanism.End Milling and Facing Machine is also provided with a small control panel with the help of which operator can easily feed the input.

Precision and Versatility for Challenging Applications

The EMFM-1150 End Milling and Facing Machine is built for rigorous industrial environments, excelling in aluminum profile milling and facing operations. Its heavy-duty steel frame, reliable V-belt drive, and integrated coolant tank provide outstanding durability and cooling, guaranteeing consistent results even in demanding production runs. Its quick-setting mechanism and manual handwheel control enable rapid adjustments to suit various operational needs.

Safety and Operator-Friendly Features

With comprehensive safety safeguards such as overload protection and an emergency stop switch, this machine prioritizes operator wellbeing. Essential accessories-including a tool kit, work clamp, and user manual-are provided to ensure smooth installation and ongoing maintenance, maximizing uptime and productivity for workshops and production lines.

Efficient and Economical Production

Operating on a 2 HP motor and manual panel with semi-automatic features, the EMFM-1150 offers high precision (0.02 mm) while maintaining an economical profile. Capable of handling up to 50 units per month, this machine delivers both high output and top-notch precision, making it a great investment for small- to medium-sized manufacturers and traders.

FAQ's of End Milling and Facing Machine:

Q: How is the EMFM-1150 End Milling and Facing Machine operated?

A: The EMFM-1150 operates in a semi-automatic mode, utilizing manual control through a handwheel and an electrical panel. This allows for precise adjustments and easy operation, ensuring accurate end milling and facing tasks.Q: What types of materials can be processed with this machine?

A: This machine is engineered to handle aluminum, PVC, and other light alloys, making it suitable for a wide range of industrial applications such as aluminum profile fabrication and facing jobs.Q: When should I use this machine for my manufacturing process?

A: The EMFM-1150 is ideal for applications requiring high-precision end milling or facing, particularly in the fabrication of aluminum profiles or parts where a profile width up to 160 mm and high accuracy are essential.Q: Where is the EMFM-1150 typically installed and used?

A: The machine is widely utilized in manufacturing plants, workshops, or fabrication units across India. It is designed for environments requiring reliable machining of light alloys and metal profiles.Q: What is the setup and tool changing process for this machine?

A: Setup involves securing the workpiece with the provided work clamp and adjusting the settings using the manual handwheel. Tool changing is performed manually with the included tool kit and follows the ISO 40 tool holder standard, allowing quick and safe cutter swaps.Q: How does the machine ensure safety during operation?

A: Equipped with overload protection and an emergency stop, the EMFM-1150 enhances operator safety. Its robust frame and control system help minimize risks during operation.Q: What are the main benefits of using this milling and facing machine?

A: Key benefits include its high precision (0.02 mm), rugged construction, fast setup, integrated coolant tank, and consistent performance under heavy-duty use. Its semi-automatic design delivers productivity with operator control, suitable for various industrial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plano Miller Machine Category

Planner Cum Plano Miller Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Usage & Applications : Used for heavy duty flat surface planning, milling, slotting, and grooving

Features : Precision engineering, rigid construction, interchangeable attachments

Frame Type : Cast Iron Bed

Noise Level : Below 80 dB

Planner Cum Plano Milling

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Heavy duty metal surfacing, slotting and shaping

Features : Robust construction, high precision, long service life

Frame Type : Heavy Duty

Noise Level : 85 dB

Plano Miller

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Heavyduty metal shaping, planing, and surface finishing

Features : Robust design, high rigidity, reliable operation, long service life

Frame Type : Rigid cast iron frame

Noise Level : <80 dB

Plano Miller Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Planing, milling, and shaping heavy and large workpieces

Features : High rigidity, robust construction, interchangeable heads

Frame Type : Heavy Duty

Noise Level : Approx. 75 dB

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS