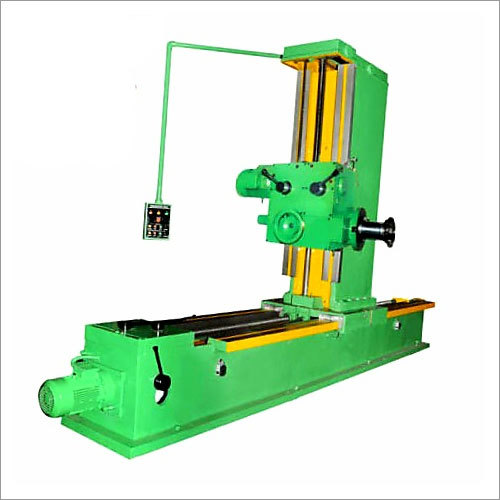

Plano Miller Machine

Plano Miller Machine Specification

- Model No

- PLM-3500

- Lubricating System

- Centralized lubrication

- Frequency

- 50 Hz

- Motor Power

- 15 HP

- Operating Temperature

- 5C to 45C

- Control System

- Manual/Relay Control

- Features

- High rigidity, robust construction, interchangeable heads

- Machine Type

- Milling & Planing

- Power Rating

- 11 kW

- Voltage

- 415 V

- Drive

- Gear driven

- Frame Type

- Heavy Duty

- Cooling System

- Flood coolant

- Accuracy

- 0.02 mm

- Noise Level

- Approx. 75 dB

- Production Capacity

- Suitable for large batch production

- Product Type

- Plano Miller Machine

- Technology

- Conventional machining

- Power Source

- Electric

- Operating Type

- Semi-Automatic

- Power

- 15 HP

- Pressure

- Standard atmospheric pressure

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- 3500 x 1500 x 1500 mm

- Weight (kg)

- Approx. 5000 kg

- Color

- Blue/Grey

- Usage & Applications

- Planing, milling, and shaping heavy and large workpieces

- Main Spindle Taper

- ISO 50

- Feed Rate

- Adjustable

- Table T-Slot Width

- 22 mm

- Warranty Coverage

- Mechanical and electrical parts

- Maximum Table Length

- 3000 mm

- Foundation Requirements

- Heavy foundation recommended

- Safety Features

- Emergency stop, overload protection

- Power Consumption

- Approx. 13 kW

- Table Travel

- Up to 3000 mm

- Number of Milling Heads

- 2

- Table Surface Hardness

- >HB220

- Maximum Table Width

- 1250 mm

- Spindle Speed Range

- 40 - 1200 rpm

- Max Load on Table

- 4000 kg

- Maximum Height Under Cross Rail

- 1200 mm

Plano Miller Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Plano Miller Machine

Exceptional Heavy-Duty Performance

Designed for large batch production, the PLM-3500 Plano Miller Machine caters to manufacturing environments requiring the processing of heavy and oversized components. With dual milling heads, robust spindle power, and a heavy-duty gear-driven frame, it meets the toughest machining demands for planing, milling, and complex shaping tasks.

Precision, Safety, and Efficiency Combined

This machine offers a superior blend of accuracy (0.02 mm), adjustable feed rates, reliable overload protection, and an emergency stop function. Armored with a rigid, paint-coated structure and centralized lubrication, operators achieve consistent and precise results while benefiting from a quieter environment (approx. 75 dB) and an efficient cooling system for prolonged operation.

Versatile Applications Across Industries

Suitable for tool rooms, heavy equipment manufacturing, and engineering workshops, the PLM-3500 excels in routines where strength, accuracy, and adaptability are paramount. Its capacity to work on large workpieces with a high table load makes it the preferred choice for fabricators and machinists across India.

FAQ's of Plano Miller Machine:

Q: What are the key features and benefits of the Plano Miller Machine PLM-3500?

A: The PLM-3500 offers a large milling capacity (table 1250 mm x 3000 mm), high load support (up to 4000 kg), two milling heads, adjustable feed rates, precise machining (0.02 mm accuracy), and sturdy gear-driven construction. Its robust design, centralized lubrication, and flood coolant system promote consistent performance and durability. Safety is enhanced with emergency stop and overload protection.Q: How can I use the machine for large or heavy workpieces?

A: The machine's spacious table and powerful drive system are specifically built to handle oversized or heavy components up to 4000 kg. Simply secure your workpiece using the 22 mm T-Slots and set the milling heads as required. The dual-head system and adjustable feed rates ensure efficient and uniform machining across large surfaces.Q: Where is the Plano Miller Machine PLM-3500 best utilized?

A: This machine is highly valued in heavy engineering workshops, tool rooms, and factories engaged in large-scale or batch production, especially where heavy-duty planing, milling, and shaping of large workpieces are routine tasks. Its robustness and versatility make it suitable for industries such as fabrication, component manufacturing, and heavy equipment production.Q: When should regular maintenance or servicing be performed?

A: It is recommended to follow standard industrial maintenance schedules-daily checks for lubrication oil, coolant levels, and wear; weekly inspections of moving parts; and periodic servicing as per the manufacturer's manual to ensure lasting performance. Regular maintenance helps prevent breakdowns and extends the machine's operating life.Q: What foundation and power supply requirements should I prepare for?

A: A heavy foundation is advised to support the machine's weight (approx. 5000 kg) and ensure vibration-free operation. The power supply should meet specifications: 415 V, 50 Hz, with an approximate power consumption of 13 kW and a main motor rated at 15 HP. Proper installation ensures operational reliability and user safety.Q: How safe is the operation process for the Plano Miller Machine?

A: The machine includes several safety features, including emergency stop and overload protection, to safeguard operators during use. The centralized lubrication system helps prevent overheating, and the flood coolant system maintains optimal machining temperatures, further contributing to a safe working environment.Q: What kind of warranty and after-sales service does the machine offer?

A: The PLM-3500 comes with warranty coverage on mechanical and electrical parts. Please consult with your distributor or supplier in India for detailed terms and post-sale support, including spare parts, maintenance, and technical assistance as needed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plano Miller Machine Category

Planner Cum Plano Milling

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue & Grey

Control System : Other, Semiautomatic/PLC compatible

Weight (kg) : Approx. 8000 kg

Surface Treatment : Other, Paint Coated

Planner Cum Plano Miller Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Color : Blue & White

Control System : Other, Panel Operated

Weight (kg) : 8200 kg

Surface Treatment : Other, Paint Coated

Plano Miller

Price Range 100000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue / Grey

Control System : Other, Manual/PLC optional

Weight (kg) : Approx. 7000 kg

Surface Treatment : Other, Paint Coated

End Milling and Facing Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue & Silver

Control System : Other, Manual Handwheel & Electrical Panel

Weight (kg) : 225 kg

Surface Treatment : Other, Powder Coated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free