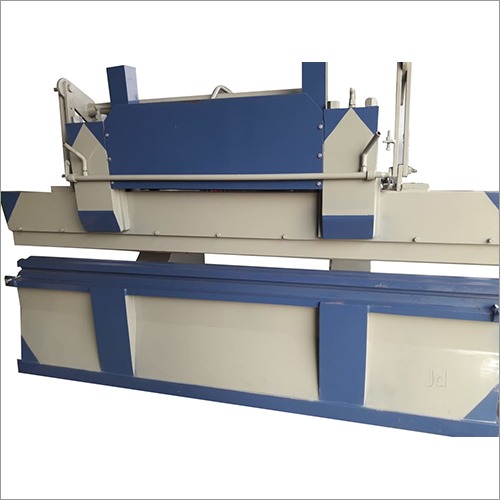

Plate Bending Machine

MOQ : 1 Piece

Plate Bending Machine Specification

- Bend Radius

- min 50 mm

- Production Capacity

- 2-4 pieces per hour

- Bending Strength

- up to 350 MPa

- Automation

- Semi Automatic

- Product Type

- Plate Bending Machine

- Machine Type

- Hydraulic Plate Bending Machine

- Place of Origin

- India

- Raw Material

- Mild Steel

- Dimension (L*W*H)

- 3200 mm x 1200 mm x 1500 mm

- Voltage

- 415 V

- Phase

- Three Phase

- Weight

- 3200 kg

- Condition

- NEW

- Power

- 7.5 kW

- Output

- Curved/Bent Plate

- Bending Angle

- 0 to 360

- Capacity

- 6mm x 2500mm (plate thickness x width)

- Usage

- Industrial Sheet Bending

- Color

- Blue & White

- Motor Speed

- 1440 rpm

- Bending Speed

- 3 m/min

- Safety Features

- Emergency Stop, Safe Guards

- Frame Material

- Heavy Duty Steel Structure

- Surface Finish

- Powder Coated

- Noise Level

- Below 75 dB

- Back Roll Adjustment

- Manual & Motorized

- Roller Quantity

- 3 Rollers

- Control System

- Electric Panel

- Roll Material

- Alloy Steel

- Max Roll Opening

- 160 mm

- Lubrication Type

- Centralized Grease Lubrication

Plate Bending Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Plate Bending Machine

Plate Bending Machine is unmatched in terms of design and quality. It is typically used in industries including mechanical, automobile, metalworking, etc for varied applications including plate bending and material shaping. This machine has got high build quality and ergonomic design, therefore, the operator can effortlessly work with the machine. Owing to its capability of enduring impacts, rust, and tough climate conditions, the demand for the machine is high in the marketplace.

Precision Engineering for Reliable Performance

The hydraulic plate bending machine is designed with three robust alloy steel rollers and a heavy-duty steel frame. It delivers consistent bending results on mild steel plates, ensuring accurate outputs for industrial needs. With a motorized and manual back roll adjustment, users can make precise modifications efficiently.

Enhanced Safety and Operator Comfort

Operator safety is prioritized through safe guard systems, emergency stops, and a centralized grease lubrication setup. The machine's noise level remains below 75 dB, providing a more comfortable working environment in busy manufacturing units.

Versatility and Efficient Sheet Bending

Capable of handling plates up to 6 mm thick and 2500 mm wide, this semi-automatic machine achieves a bending angle from 0 to 360, supporting varied industrial applications. Its powerful 7.5 kW motor and 1440 rpm speed enable efficient output rates, producing up to 4 pieces per hour.

FAQ's of Plate Bending Machine:

Q: How does the plate bending process work in this hydraulic machine?

A: The process involves inserting a mild steel plate between three alloy steel rollers. The hydraulic system and adjustable back roll allow precise manipulation, curving or bending the plate as per the required angle, from 0 up to 360. Both motorized and manual adjustments offer flexibility in forming operations.Q: What are the key safety features included in this machine?

A: Safety is prioritized with emergency stop buttons, effective safe guards, and a centralized grease lubrication system that reduces maintenance risks. The design ensures operators are protected during operation, and the low noise level further promotes workplace safety.Q: When should I choose this plate bending machine for my production line?

A: This machine is ideal when your production requires robust, accurate bending of mild steel sheets up to 6 mm thick and 2500 mm in width. Its semi-automatic controls and efficient output (2-4 pieces per hour) suit medium to high-volume industrial applications.Q: Where is this hydraulic plate bending machine manufactured and distributed?

A: Manufactured in India, this machine is supplied, distributed, and traded nationwide by reputable distributors, manufacturers, and suppliers catering to industrial sheet bending requirements.Q: What are the main benefits of using a three-roll hydraulic plate bending machine?

A: The machine offers reliable curved or bent plate production, high precision thanks to alloy steel rollers, low operation noise, and enhanced safety. The centralized lubrication and heavy-duty frame reduce downtime and improve longevity.Q: How is the machine operated and controlled?

A: Operation is managed through an electric control panel, with manual or motorized options for back roll adjustment. The semi-automatic system allows operators to control the bending process efficiently and safely.Q: What types of industrial applications is this plate bending machine suitable for?

A: It is well-suited for industrial sheet forming, manufacturing pressure vessels, construction components, and fabricating large curved steel parts, particularly where consistent, high-quality bends are required.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Bending Machine Category

Sheet Bending Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Sheet Bending Machine

Place of Origin : India

Usage : Industrial Sheet Bending

Machine Type : Mechanical

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS