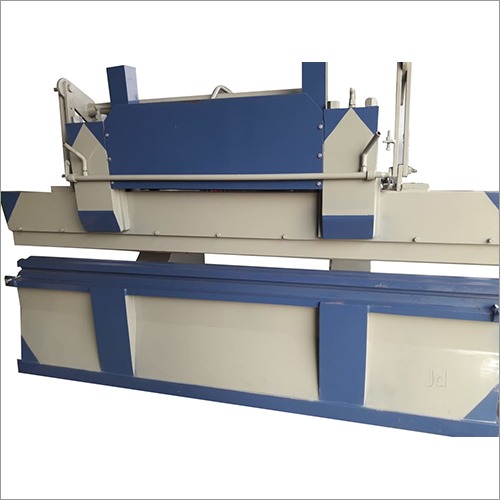

Sheet Bending Machine

MOQ : 1 Piece

Sheet Bending Machine Specification

- Capacity

- Up to 2.5 mm sheet thickness

- Machine Type

- Mechanical

- Usage

- Industrial Sheet Bending

- Motor Speed

- 1440 RPM

- Power

- 2-5 HP

- Weight

- 1200 kg

- Bending Speed

- 12-18 bends/min

- Production Capacity

- 1000 Sheets/Day

- Product Type

- Sheet Bending Machine

- Phase

- Three Phase

- Raw Material

- Mild Steel

- Output

- Straight and curved bends

- Voltage

- 220-440V

- Automation

- Manual

- Place of Origin

- India

- Bending Angle

- 0-135

- Dimension (L*W*H)

- 2400 mm x 800 mm x 1200 mm

- Bending Strength

- Up to 16 gauge

- Bend Radius

- 1.5 mm minimum

- Condition

- NEW

- Color

- Blue-Grey

- Service

- On-site Installation & Training available

- Blade Type

- Hardened Alloy Steel Blades

- Frame Material

- Heavy Duty Steel

- Lubrication Type

- Grease Nipples Provided

- Included Accessories

- Standard Bending Tools and Die Set

- Clamping Type

- Manual Clamping

- Operation Mode

- Lever/Hand Operated

- Surface Finish

- Painted/Polished

- Noise Level

- Low

- Safety Features

- Hand Safety Guard Provided

Sheet Bending Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Sheet Bending Machine

Sheet Bending Machine that we are offering is popularly known among our customers owing to its superior design and performance. This bending machine is unmatched in terms of reliability and quality. Having rugged construction and the capability of enduring impacts, rust, and tough climate, this machine ensures longevity. Sheet Bending Machine is used in industries including metalworking, mechanical, automobile, among others. It is available in a plethora of sizes and technical configurations. Our customers can approach us to purchase the Sheet Bending Machine at a reasonable price.

Heavy-Duty Construction for Long-Term Reliability

Engineered with a robust steel frame and a painted or polished finish, this machine ensures exceptional durability in demanding industrial environments. Heavy-duty materials and safety features like hand guards maximize both longevity and operator protection during sheet bending operations.

Efficient Manual Operation with Precision Bending

The hand/lever operated system, equipped with manual clamping and hardened alloy steel blades, empowers users to achieve accurate bends up to 135 on mild steel sheets. The machine is capable of producing straight and curved bends, with a minimum bend radius of 1.5 mm, making it suitable for a variety of industrial applications.

Comprehensive Support and Accessories Included

Each unit comes complete with standard bending tools, die sets, grease nipples for smooth operation, and on-site installation and training. This ensures you get immediate value, straightforward setup, and confident operation right from the start.

FAQ's of Sheet Bending Machine:

Q: How does the manual clamping mechanism work on this sheet bending machine?

A: The manual clamping system uses a hand lever to securely hold the sheet in place before bending. This method ensures precise positioning and allows users to make adjustments easily during operation.Q: What type and thickness of material can this machine handle?

A: This machine is designed for mild steel sheets with a thickness capacity of up to 2.5 mm and a bending strength of up to 16 gauge, making it ideal for a broad range of industrial sheet bending tasks.Q: When should I use the included lubrication system?

A: Grease nipples are provided for routine lubrication, which should be done according to your usage frequency-typically before daily operation or after every 100 bends-to ensure smooth and reliable machine movement.Q: Where can I access installation and training services?

A: On-site installation and training services are available throughout India. Once your machine is delivered, qualified technicians will ensure proper setup and provide operational training at your facility.Q: What is the general process of operating this lever/hand operated machine?

A: Simply load the sheet, use the manual clamp to secure it, operate the lever to perform the bend, and repeat as needed. The machine allows adjustment for different angles (0-135) and produces up to 1000 sheets per day, depending on operator speed.Q: How does the machine enhance safety during use?

A: A hand safety guard is integrated into the design, reducing the risk of accidental injury. The low-noise operation also contributes to a safer and more comfortable working environment.Q: What are the key benefits of using this sheet bending machine in an industrial setting?

A: Users benefit from the machine's robust construction, high productivity (up to 18 bends per minute), consistent bending accuracy, comprehensive accessory package, and strong after-sales support, ensuring efficient and reliable operations over the long term.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Bending Machine Category

Plate Bending Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Phase : Three Phase

Product Type : Plate Bending Machine

Capacity : 6mm x 2500mm (plate thickness x width)

Voltage : 415 V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS