Structure Rolling Mill

Structure Rolling Mill Specification

- Temperature Range

- Up to 1200C

- Usage & Applications

- Hot rolling structural sections (angles, channels, beams)

- Driven Type

- Electric

- Accessories

- Roll sets, Lubrication system, Cooling bed

- Frequency

- 50/60 Hz

- Efficiency (%)

- Up to 92%

- Motor Power

- Up to 200 HP

- Model No

- SRM-2024

- Automation Grade

- Semi-Automatic

- Installation Guideline

- On-site support available

- Production Capacity

- Up to 100 tons/day

- Speed

- Variable, up to 1200 RPM

- Type

- Structure Rolling Mill

- Material

- High Grade Steel

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Voltage

- 380-440V

- Power

- Up to 200 kW

- Weight (kg)

- Approx. 20000 kg

- Dimension (L*W*H)

- Customization Available

- Color

- Industrial Grey

- Capacity

- Custom as per requirement

- Features

- High precision rolling, Robust design, Energy efficient

- Power Consumption

- Varies with Model

- Surface Finish

- Mill Finish

- Machine Type

- Rolling Mill Machine

- Mill Stand Type

- Housing-less

- Number of Stands

- Up to 12

- Noise Level

- < 80 dB

- Cooling Bed Length

- Customizable

- Roll Material

- Alloy Steel

- Emergency Stop

- Available

- Gear Box

- Heavy Duty

- Roll Diameter

- Up to 600 mm

- Operation Mode

- Continuous & Batch

- After Sales Support

- Available

- Oil Lubrication System

- Integrated

- Foundation Requirement

- Standard Industrial

- Bearing Type

- Heavy Duty Sleeve Bearings

- Safety Features

- Interlock System, Guards

- Input Material

- Billet, Bloom

- Packaging Detail

- Standard Export Packaging

- Workpiece Thickness Range

- 10 mm to 300 mm

- Maintenance

- Low maintenance design

Structure Rolling Mill Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Structure Rolling Mill

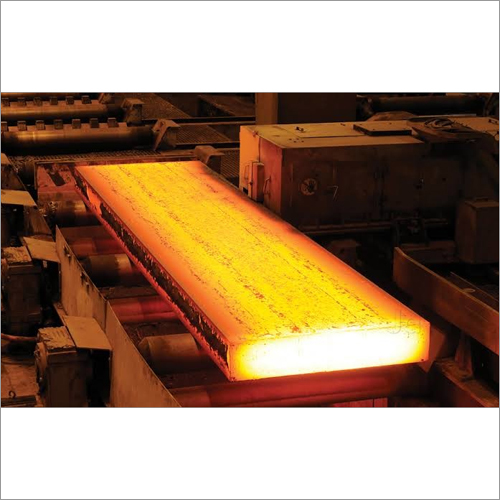

Structure Rolling Mill provided by our company, is designed and manufactured by making use of premium grade of raw materials and upgraded technology. This mill is tested under various parameters to ensure its effectiveness and flawlessness. This mill can feed your metal through to either change the shape and thickness. Structure Rolling Mill is very easy to install as well as simple to use. This mill is very economical and can be easily availed at nominal rates, as per their requirements.

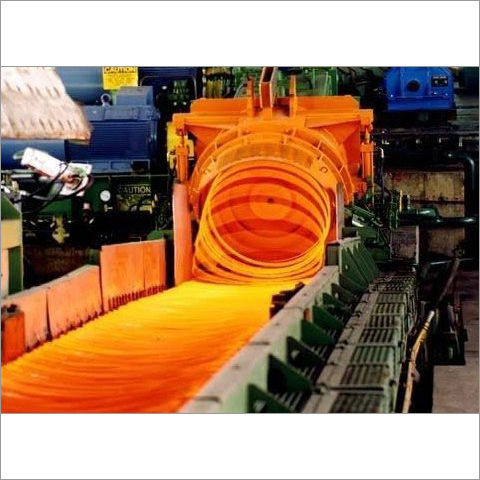

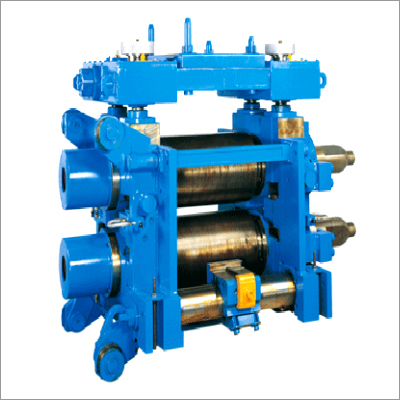

Precision Engineering for Enhanced Productivity

The SRM-2024 Structure Rolling Mill employs a robust PLC control system and variable-speed motors to achieve high-precision rolling with exceptional repeatability. Its customizable configuration and advanced metallurgical capabilities allow processing of billets and blooms into structural components of varying thicknesses, ranging from 10 mm to 300 mm.

Safety and Reliability at Every Step

This rolling mill incorporates advanced interlock systems, safety guards, and emergency stop functions for operator safety. The housing-less stand design and heavy-duty gearbox provide operational stability while the integrated oil lubrication and low maintenance requirements ensure high uptime and operational reliability.

Flexible Design for Custom Applications

With customizable cooling bed lengths and dimension options, the SRM-2024 accommodates a range of client requirements. Its adaptable voltage, power, and layout options paired with export packaging make it ideal for manufacturers, distributors, and suppliers across India and international markets.

FAQ's of Structure Rolling Mill:

Q: How does the SRM-2024 rolling mill handle different structural profiles and workpiece thicknesses?

A: The SRM-2024 is engineered with up to 12 housing-less stands and roll diameters up to 600 mm, enabling precise rolling of structural profiles such as angles, channels, and beams across a thickness range of 10 mm to 300 mm, customizable per production needs.Q: What safety features are included in the operation of this structure rolling mill?

A: Safety is prioritized with advanced interlock systems, protective guards, and a dedicated emergency stop function. Compliance with industrial noise regulations (<80 dB) and operator safety standards is integral to the mill's design.Q: When is on-site installation or support provided for the SRM-2024?

A: On-site installation guidance is available upon request. Our after-sales support team can coordinate installation schedules and provide training to ensure optimal setup and safe operation.Q: Where can the SRM-2024 be installed, and what are the foundation requirements?

A: The SRM-2024 is designed for standard industrial foundations. With customizable dimensions, it fits various facility layouts, suitable for manufacturers, suppliers, and traders across India and abroad.Q: What is the process flow for hot rolling structural sections with this machine?

A: Input material such as billets or blooms is fed into the mill, passing through a sequence of heavy-duty, precision-controlled rolling stands. The finished structural sections are then conveyed to the customizable cooling bed, ensuring optimal surface finish and material properties.Q: How does its PLC control and semi-automatic design benefit production efficiency?

A: PLC-based automation regulates key process parameters and enables easy operation. The semi-automatic workflow streamlines production management, reducing downtime, enhancing product consistency, and improving overall efficiency up to 92%.Q: What after-sales services and export packaging options are available?

A: Comprehensive after-sales support includes technical assistance, spare parts, and on-site services. Machines are shipped with standard export packaging for secure transit, ensuring they arrive safely at your site, ready for installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Rolling Mill Plant Workshop Machine Category

Wire Rod Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Control System : PLC Control

Computerized : Yes

Voltage : 220V480V

Hot Steel Rolling Mill Plant Workshop

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Other, Automatic/SemiAutomatic

Control System : Other, PLC based

Computerized : Yes

Voltage : 380440 V

Section Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Control System : Other, PLC Controlled

Computerized : Yes

Voltage : 380440 V

Light and Medium Section Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Control System : Other, PLC Based

Computerized : Yes

Voltage : 380440 V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free