Wire Rod Rolling Mill

Wire Rod Rolling Mill Specification

- Production Capacity

- Up to 500,000 Tons Per Annum

- Accessories

- Rolls, Guide boxes, Water cooling system, Lubrication system, Automation panel

- Temperature Range

- 900C 1200C (working temperature range for rolling)

- Usage & Applications

- Wire rod manufacturing for construction, automotive, and engineering applications

- Model No

- WRRM1000

- Driven Type

- Gear Driven/Electric Motor Driven

- Frequency

- 50/60 Hz

- Automation Grade

- Fully Automatic

- Speed

- Up to 100 m/s

- Plastic Processed

- N/A Metal Processing Equipment

- Motor Power

- 75-1100 kW (depending on mill size)

- Efficiency (%)

- Over 90%

- Installation Guideline

- Supplied with installation manual and technical support

- Type

- Wire Rod Rolling Mill

- Material

- Mild Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 220V-480V

- Power

- 100-1200 kW (Varies by configuration)

- Weight (kg)

- 35000 Kg (Approx.)

- Dimension (L*W*H)

- Customized as per requirement

- Color

- Industrial Blue/Grey

- Capacity

- 10 to 100 tons/hour

- Features

- High strength, Precision engineering, Long life, Energy efficient

- Power Consumption

- Depends on configuration

- Machine Type

- Wire Rod Finishing Mill

- Surface Finish

- Smooth, scale-free rods

- Roll Arrangement

- Horizontal and Vertical stands

- Line Speed

- Variable frequency drive controlled

- Lubrication System

- Centralized automatic

- Operator Interface

- Touchscreen HMI

- Max Output Rod Size

- 5.5 mm to 32 mm

- Cooling Process

- Water-cooled System

- Roll Diameter

- 200-450 mm

- Spindle Type

- Universal Joint Coupling

- Billet Size

- 100x100 mm up to 180x180 mm

- Noise Level

- Below 85 dB

- Annual Output

- Up to 150,000 tons

- Pre-heating Method

- Induction/Conventional

- Foundation Requirement

- Heavy-duty RCC foundation

- Roll Material

- Forged Alloy Steel

Wire Rod Rolling Mill Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Wire Rod Rolling Mill

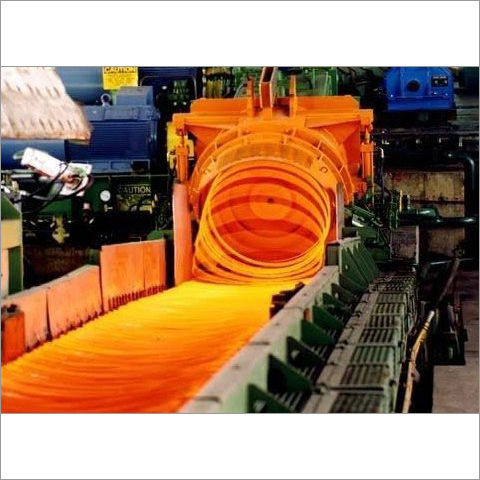

Our company, SACH KHAN MACHINE TOOLS, is the best provider of Wire Rod Rolling Mill in the Indian market. This mill machine is constructed from chemical and water resistant metal, ensuring it lasts decades with negligible maintenance. It is easy to install and extensively used to roll metal wired into linear shape for further processing. The provided Wire Rod Rolling Mill is effectively resistant against greases, stains, and debris, making the structure immaculate for a long period.

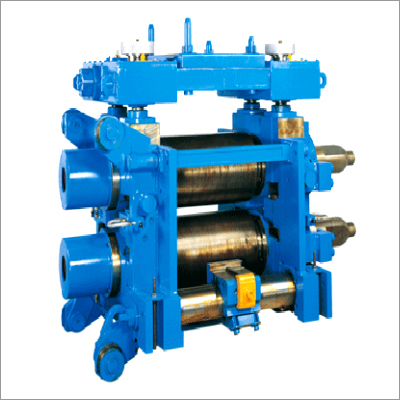

Advanced Automation and Drive Control

The WRRM1000 incorporates state-of-the-art PLC control with a user-friendly touchscreen HMI. Its variable frequency drive allows precise speed adjustment, contributing to over 90% efficiency during operation. The centralized automatic lubrication system and universal joint coupling spindles further optimize performance and extend equipment lifespan.

Superior Quality and High Output

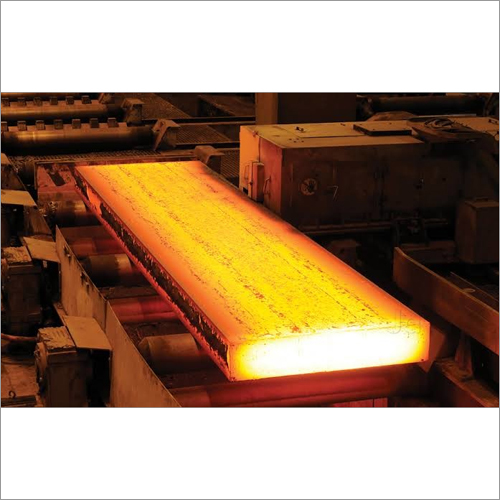

This rolling mill ensures repeatable, scale-free surface finishes with billets ranging from 100x100 mm to 180x180 mm. Engineered for high-capacity operation, the mill can produce up to 500,000 tons of wire rods annually. Its heavy-duty build and efficient water-cooled system allow processing at working temperatures between 900C and 1200C, suitable for continuous, demanding production cycles.

FAQs of Wire Rod Rolling Mill:

Q: How does the WRRM1000 ensure consistent rod quality and finish?

A: The WRRM1000 uses precision-engineered forged alloy steel rolls and a sophisticated water-cooled system for optimal temperature control. Its horizontal and vertical roll arrangements, combined with automatic lubrication, result in scale-free, smooth-surfaced rods throughout production.Q: What is the capacity and output range of this wire rod rolling mill?

A: Depending on configuration, the mill can handle an annual production capacity ranging from 150,000 up to 500,000 tons, with hourly rates between 10 and 100 tons. Output diameters span from 5.5 mm to 32 mm, making it suitable for both small and large production facilities.Q: When is the centralized automatic lubrication system activated?

A: The centralized lubrication system is programmed to operate automatically during mill running cycles. It ensures continuous lubrication to critical components, reducing wear and required manual intervention, which in turn extends equipment service life and reduces downtime.Q: Where is the WRRM1000 typically installed and what are the foundation requirements?

A: The WRRM1000 is installed in industrial environments such as construction material manufacturing units, automotive part plants, and engineering product facilities. Installation requires a heavy-duty RCC (reinforced cement concrete) foundation to support its weight and dynamic loads during operation.Q: What pre-heating options are available for billets in this mill?

A: The WRRM1000 supports both induction and conventional pre-heating methods, allowing billets to reach the ideal rolling temperature between 900C and 1200C. The choice depends on production volume, energy considerations, and application needs.Q: How is operator interaction streamlined during mill operation?

A: Operators benefit from a touchscreen HMI interface, enabling efficient process monitoring, parameter adjustments, and fault diagnostics. The PLC-based control system also provides real-time data visualization for enhanced control and safety.Q: What are the key advantages of using this wire rod rolling mill?

A: Major advantages include high production efficiency, low noise emission (below 85 dB), energy-saving operation, fully automatic and computerized control, robust construction, and adaptability for customized layouts. These features ensure reliable, cost-effective operation for wire rod manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Rolling Mill Plant Workshop Machine Category

Structure Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Mill Finish

Automatic Grade : SemiAutomatic

Voltage : 380440V

Installation Guideline : Onsite support available

Hot Steel Rolling Mill Plant Workshop

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Smooth, uniform, customizable

Automatic Grade : Other, Automatic/SemiAutomatic

Voltage : 380440 V

Installation Guideline : Onsite installation & commissioning by experts

TMT Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Polished / Painted

Automatic Grade : Automatic

Voltage : 380440 V

Installation Guideline : Onsite assembly with professional supervision

Light and Medium Section Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Finish : Other, Polished / Painted

Automatic Grade : Automatic

Voltage : 380440 V

Installation Guideline : Professional Onsite Installation

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free