TMT Rolling Mill

TMT Rolling Mill Specification

- Frequency

- 50/60 Hz

- Efficiency (%)

- Up to 95%

- Installation Guideline

- On-site assembly with professional supervision

- Model No

- TMT-6601357

- Automation Grade

- Automatic

- Usage & Applications

- TMT bar production for construction

- Accessories

- Rolls, Motors, Gearboxes, Cooling system

- Driven Type

- Electric

- Speed

- Up to 20 m/min

- Motor Power

- Up to 250 HP

- Production Capacity

- 5-50 tons per hour

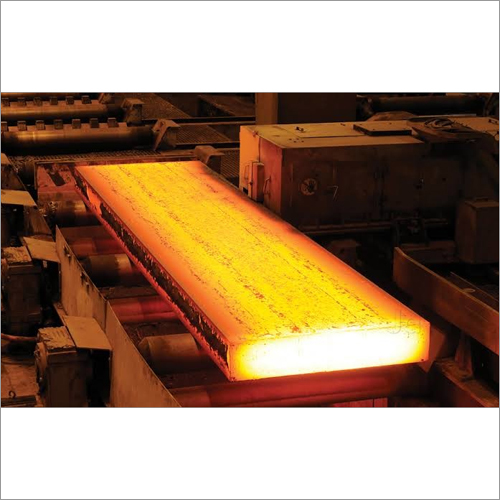

- Temperature Range

- 900C - 1200C

- Type

- Hot Rolling Mill

- Material

- Mild Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Drive Type

- Electric

- Voltage

- 380-440 V

- Power

- Variable (as per configuration)

- Weight (kg)

- Depending on mill size (customized)

- Dimension (L*W*H)

- As per design (customized)

- Color

- Blue / Customized

- Capacity

- Up to 100,000 Tons/Year

- Features

- High production capacity, robust design, precise operation, durable finish

- Surface Finish

- Polished / Painted

- Power Consumption

- Varies per configuration

- Machine Type

- TMT Bar Rolling Mill

- No. of Stands

- 6-20 (depending on configuration)

- Spare Parts

- Available on request

- Operator Requirement

- 2-5 persons per shift (approx.)

- After Sales Service

- Available

- Foundation Required

- Yes

- Re-heating Furnace Type

- Pusher Type/Oil Fired/Gas Fired

- Safety Features

- Emergency stop, protective guards, thermal sensors

- Noise Level

- Below 85 dB

- Energy Consumption

- Optimized per design

- Lubrication System

- Automatic / Centralized

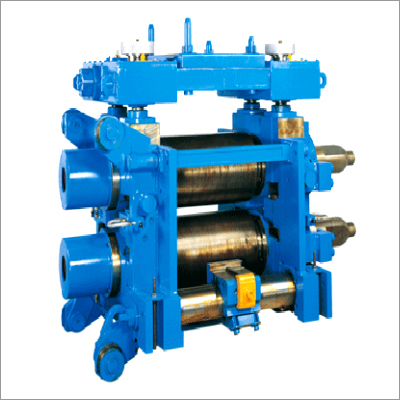

- Roll Diameter Range

- 200 mm 600 mm

- Roll Material

- Alloy Steel

- Cooling Bed Length

- 6 12 meters

TMT Rolling Mill Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

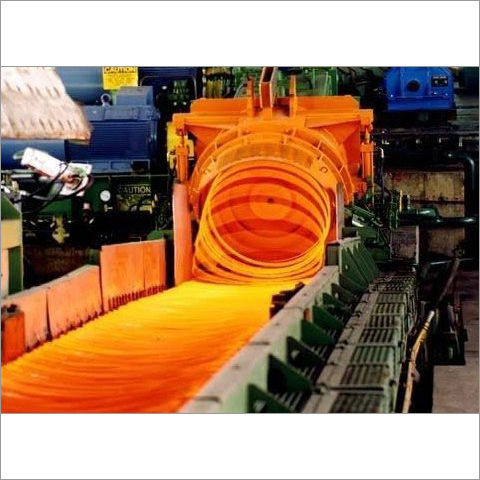

About TMT Rolling Mill

Advanced Performance and Durability

Crafted with robust alloy steel rolls and a solid structure, the TMT Rolling Mill offers precise operation and a polished surface finish. With a highly efficient drive and automation system, the mill ensures up to 95% operational efficiency, while handling high temperatures from 900C to 1200C. Its design emphasizes longevity, reduced noise, and consistent output.

Automated Control and User-Friendly Operation

Equipped with a PLC-based automated control system, this hot rolling mill guarantees ease of operation and minimal manual intervention. The central lubrication system, automatic grade controls, and effective cooling bed (6-12 meters) all contribute to streamlined usage and high production rates, maintaining operator safety and machine integrity.

Comprehensive Support and Customization

Manufactured, supplied, and distributed in India, this TMT Rolling Mill offers full installation guidance, on-site assembly, professional supervision, and after-sales services. Spare parts are available on request, and customizable features-such as dimensions, color, and electric specifications-ensure the solution suits diverse business needs.

FAQ's of TMT Rolling Mill:

Q: How does the TMT Rolling Mill ensure precise operation and high production capacity?

A: The TMT Rolling Mill utilizes a PLC-based automated control system and robust alloy steel rolls to maintain consistent quality and precision throughout the hot rolling process. Its design supports high-speed operation (up to 20 m/min) and can handle up to 50 tons per hour, resulting in a maximum annual capacity of 100,000 tons.Q: What are the safety features included in the TMT Rolling Mill?

A: Safety is prioritized through the inclusion of an emergency stop system, protective guards along key areas, and thermal sensors that safeguard both operators and equipment during high-temperature operations.Q: When is a foundation required for the TMT Rolling Mill installation?

A: A solid, pre-constructed foundation is mandatory before on-site assembly and installation of the TMT Rolling Mill, ensuring proper support and operational stability as guided by professional supervisors.Q: Where can I access after-sales service and spare parts for this rolling mill?

A: After-sales service and spare parts are readily available upon request through the manufacturer, supplier, or distributor in India, supporting your ongoing operational needs and maintenance requirements.Q: What is the process for setting up and operating the TMT Rolling Mill?

A: The setup involves on-site assembly with professional supervision, installation of key accessories (rolls, motors, gearboxes), and calibration of the PLC-based control system. Operator teams (2-5 per shift) are then trained for safe and efficient use.Q: How is energy consumption optimized in the TMT Rolling Mill?

A: Energy efficiency is central to the mill's design, with variable power configurations, advanced electric drives, and automatic systems that minimize excess energy use, resulting in lower operational costs for users.Q: What are the main benefits of using this TMT Rolling Mill for TMT bar production?

A: Users benefit from high efficiency (up to 95%), durable performance, customizable options, advanced safety measures, and reliable after-sales support, making it a valuable asset for construction material production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Rolling Mill Plant Workshop Machine Category

Wire Rod Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Wire Rod Finishing Mill

Material : Mild Steel

Type : Wire Rod Rolling Mill

Features : High strength, Precision engineering, Long life, Energy efficient

Structure Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Rolling Mill Machine

Material : High Grade Steel

Type : Structure Rolling Mill

Features : High precision rolling, Robust design, Energy efficient

Section Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Rolling Mill Machinery

Material : Stainless Steel / Alloy Steel / Mild Steel

Type : Section Mill

Features : High Precision, Durable Structure, Low Maintenance, Efficient Operation

Hot Steel Rolling Mill Plant Workshop

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Steel Rolling Mill

Material : Heavyduty steel, alloy steels

Type : Hot Steel Rolling Mill Plant Workshop

Features : High precision rolling, robust construction, energy efficient, low maintenance, high production rate

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS