Section Mill

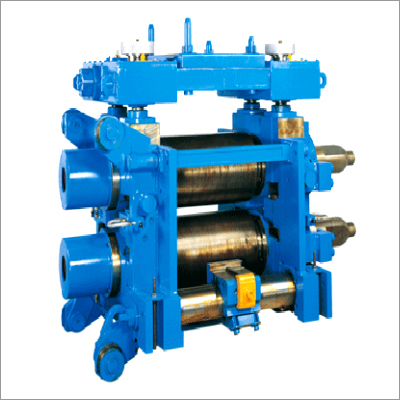

Section Mill Specification

- Motor Power

- 50-500 HP

- Frequency

- 50/60 Hz

- Production Capacity

- Up to 30,000 tons per annum

- Automation Grade

- Fully Automatic

- Driven Type

- Motor/AC Drive

- Model No

- As Per Requirement

- Usage & Applications

- Section Rolling for Beams, Channels, Angles, Rails

- Installation Guideline

- Professional Installation Required

- Efficiency (%)

- Up to 95%

- Temperature Range

- Ambient to 1200°C

- Accessories

- Rollers, Gear Couplings, Lubrication System

- Speed

- Variable, Up to 1,000 RPM

- Type

- Section Mill

- Material

- Stainless Steel / Alloy Steel / Mild Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Voltage

- 380-440 V

- Power

- Up to 500 kW

- Weight (kg)

- According to Model

- Dimension (L*W*H)

- Customized

- Color

- Industrial Grey / Blue

- Capacity

- Up to 100 tons per hour

- Features

- High Precision, Durable Structure, Low Maintenance, Efficient Operation

- Surface Finish

- Polished / Painted

- Machine Type

- Rolling Mill Machinery

- Power Consumption

- Based on Configuration

Section Mill Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

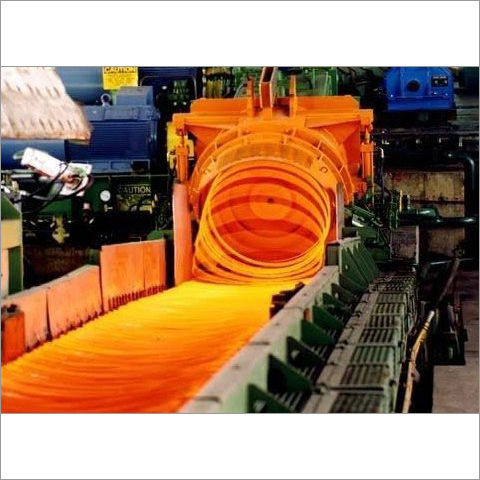

About Section Mill

The Section Mill is effectively supplied to the Indian industries by our company for years. This mill is constructed from mechanically treated metals to protect the integrated components from corrosion, short-circuits, water, and other elements. It is compactly structured by using advanced machines and technologies. The provided Section Mill is available in both semi-automatic and automatic models to streamline production processes. This mill takes less space and time during the installation process. It is easy to operate and consumes less energy.

Engineered for High Precision and Productivity

With its variable speed (up to 1,000 RPM) and a substantial capacity of up to 100 tons per hour, the Section Mill combines cutting-edge automation and durable materials for exceptional output. Each component, from alloy steel rolls to the centralized lubrication system, is tailored for sustained high performance, making it the preferred choice for industrial section rolling.

Safety and Ease of Maintenance Built In

The mill prioritizes operator safety and ease of maintenance, featuring emergency stops, interlocked safety guards, and openable covers for unobstructed access. Maintenance is simplified, reducing downtime and maximizing throughput. Its compliant design (ISO 9001:2015, CE) ensures adherence to stringent safety and quality norms.

Flexible, Efficient Operations in Challenging Environments

Capable of running in up to 90% ambient humidity and temperatures up to 1200C, this mill is ideal for demanding factory spaces. It arrives in either knocked-down or assembled condition, ensuring smooth installation, and can be tailored with accessories and spare parts upon request, supporting seamless operation in diverse steel production settings.

FAQ's of Section Mill:

Q: How does the quick change capability of the Section Mill enhance productivity?

A: The Section Mill's quick change capability allows roll and setup changes in less than 30 minutes, reducing downtime and improving overall production efficiency. This feature helps operators adapt quickly to changing section requirements, maximizing output with minimal interruption.Q: What safety features are integrated into the Section Mill to protect operators?

A: The mill includes multiple safety measures such as emergency stop buttons, safety guards, and interlock systems. These features are designed to prevent accidents, ensuring operator protection during use and maintenance, and ensuring compliance with ISO and CE standards.Q: When should routine maintenance be performed, and how accessible are service points?

A: Routine maintenance should be scheduled as per the manufacturer's recommendations, which typically depend on usage intensity and operating hours. The mill is designed with openable covers, making all critical components easily accessible for inspection, servicing, and parts replacement.Q: Where can the Section Mill be installed, and are there any specific foundation requirements?

A: The Section Mill is suitable for installation in steel plants, structural fabrication shops, and similar industrial environments. It requires a heavy-duty RCC (reinforced cement concrete) foundation to ensure stability and performance, and professional installation is recommended.Q: What is the process for ordering spare parts or accessories for the Section Mill?

A: Spare parts and accessories can be ordered directly from the manufacturer, distributor, or authorized suppliers. Requests are typically fulfilled based on the model and configuration, ensuring compatibility and minimizing downtime during replacements.Q: How does the forced water/oil cooling system contribute to machine performance?

A: The forced water/oil cooling system regulates the mill's operating temperature, preventing overheating during high-intensity rolling. This maintains optimal performance levels, extends component longevity, and ensures consistent section quality.Q: What are the key benefits of using a PLC-controlled, fully automatic Section Mill?

A: A PLC-controlled, fully automatic system offers precise parameter control, enhanced process repeatability, and minimized human error. It streamlines production, improves section quality, and adapts easily to different product specifications, enabling higher efficiency and productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Rolling Mill Plant Workshop Machine Category

Wire Rod Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Control System : PLC Control

Machine Type : Wire Rod Finishing Mill

Voltage : 220V480V

Light and Medium Section Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Control System : Other, PLC Based

Machine Type : Rolling Mill

Voltage : 380440 V

Hot Steel Rolling Mill Plant Workshop

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Heavyduty steel, alloy steels

Control System : Other, PLC based

Machine Type : Steel Rolling Mill

Voltage : 380440 V

TMT Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Control System : Other, PLC Based

Machine Type : TMT Bar Rolling Mill

Voltage : 380440 V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free