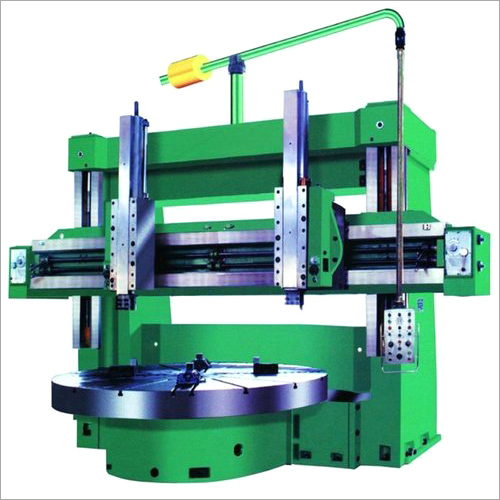

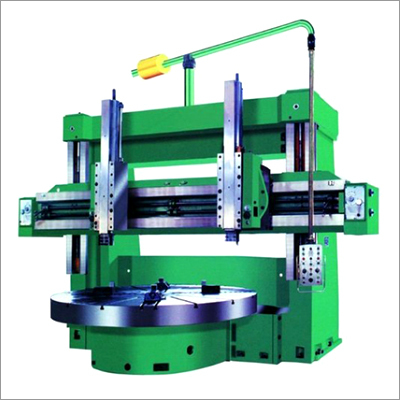

Vertical Turning Lathe Boring Machine

MOQ : 1 , , Piece

Vertical Turning Lathe Boring Machine Specification

- Product Type

- Vertical Turning Lathe Boring Machine

- Material

- Cast Iron, Steel, Alloy Steel

- Cutting Thickness

- Up to 600 mm

- Cutting Speed

- Variable, up to 500 mm/min

- CNC Or Not

- CNC and Conventional models available

- Automatic Grade

- Semi-automatic / Automatic

- Control System

- PLC / CNC (Fanuc, Siemens, etc.)

- Max. Swing Diameter

- 2000 mm

- Voltage

- 380V/415V, 3 Phase

- Weight (kg)

- Approx. 12,000 kg

- Dimension (L*W*H)

- Approx. 3200 mm x 2200 mm x 3300 mm

- Capacity

- Heavy-duty, up to 8 tons workpiece

- Feature

- Robust Structure, High Precision, Smooth Operation

- Color

- Industrial Grey/Blue

- Lubrication System

- Automatic Centralized Lubrication

- Optional Accessories

- CNC Upgrade Kit, Live Tooling, Rotary Encoder

- Standard Accessories

- Chuck, Chip Conveyor, Work Light, Tool Holders

- Positioning Accuracy

- 0.02 mm

- Main Motor Power

- 30 kW

- Noise Level

- <80 dB(A) during operation

- Operating Temperature

- 5C to 45C

- Spindle Speed Range

- 5200 rpm

- Repeatability

- 0.01 mm

- Crossrail Travel

- 1200 mm

- Boring Bar Diameter

- 120 mm max.

- Number of Tool Stations

- 4-Position Tool Turret

- Coolant System

- Integrated with Recirculation

- Table Diameter

- 2000 mm

Vertical Turning Lathe Boring Machine Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Vertical Turning Lathe Boring Machine

Introducing the Vertical Turning Lathe Boring Machine a trending, highly recommended solution for heavy-duty machining needs. Featuring a brilliant table diameter of 2000 mm, triumphant crossrail travel of 1200 mm, and robust 30 kW main motor, this praiseworthy model effortlessly accommodates workpieces up to 8 tons. Benefit from automatic centralized lubrication, integrated coolant with recirculation, and advanced positioning accuracy (0.02 mm). Available in both CNC and conventional models with optional premium add-ons at a special rate. Perfect for manufacturers, suppliers, and traders in India seeking reliable, precise machining.

Ideal Usage and Application Areas

This Vertical Turning Lathe Boring Machine is suitable for use in heavy engineering, automotive manufacturing, and fabrication workshops. Praised for its robust structure and high precision, its designed for machining oversized and complex workpieces. Application places include production floors, metalworking industries, and large machine shops. Operate the machine through its user-friendly control system, select desired speed, and engage the semi-automatic or automatic functions to achieve optimal machining results.

Premium Sample Availability and Shipping

Premium sample options are available for evaluation before making a full outlay. The machine ships from major FOB ports in India with the advantage of express shipping for prompt delivery. Serving Indias main domestic market, this product ensures quick turnaround and reliable after-sales support. Request a sample or quotation and experience the value and performance that set this vertical turning lathe boring machine apart in the heavy machinery segment.

Ideal Usage and Application Areas

This Vertical Turning Lathe Boring Machine is suitable for use in heavy engineering, automotive manufacturing, and fabrication workshops. Praised for its robust structure and high precision, its designed for machining oversized and complex workpieces. Application places include production floors, metalworking industries, and large machine shops. Operate the machine through its user-friendly control system, select desired speed, and engage the semi-automatic or automatic functions to achieve optimal machining results.

Premium Sample Availability and Shipping

Premium sample options are available for evaluation before making a full outlay. The machine ships from major FOB ports in India with the advantage of express shipping for prompt delivery. Serving Indias main domestic market, this product ensures quick turnaround and reliable after-sales support. Request a sample or quotation and experience the value and performance that set this vertical turning lathe boring machine apart in the heavy machinery segment.

FAQs of Vertical Turning Lathe Boring Machine:

Q: How does the automatic centralized lubrication system benefit machine operation?

A: The automatic centralized lubrication system ensures continuous, efficient lubrication of all moving parts, minimizing wear and reducing maintenance downtime, thereby extending machine life and improving operational reliability.Q: What types of industries commonly use this Vertical Turning Lathe Boring Machine?

A: This machine is highly recommended for heavy engineering, automotive, metal fabrication, and manufacturing sectors needing precise, robust performance for large and heavy workpieces.Q: When is it suitable to opt for the CNC upgrade kit?

A: Select the CNC upgrade kit if you require advanced automation, complex machining operations, and enhanced productivity for your production lines.Q: Where can I see a demonstration or request a sample?

A: You can request a premium sample or see a demonstration by contacting the manufacturer, distributor, or supplier, who typically arrange demos at their facilities or customer sites within India.Q: What is the process for installation and commissioning?

A: Upon purchase, the manufacturer provides end-to-end support including delivery, on-site installation, commissioning, and operator training, ensuring the machine is ready for productive use.Q: How does the integrated coolant system improve usage?

A: The integrated coolant system with recirculation maintains optimal cutting temperatures, enhances tool life, improves finish quality, and enables smoother operation during high-load machining tasks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Vertical Turning Lathe Machines Category

Vertical Turning Lathe Machines

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Other, Vertical Turning Lathe Machine

Cutting Speed : 10 400 mm/min

Material : Cast Iron, Alloy Steel

Cutting Thickness : Up to 300 mm

VTL Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Other, Vertical Turning Lathe (VTL)

Cutting Speed : Up to 60 m/min

Material : Cast Iron, Mild Steel

Cutting Thickness : Up to 400 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS