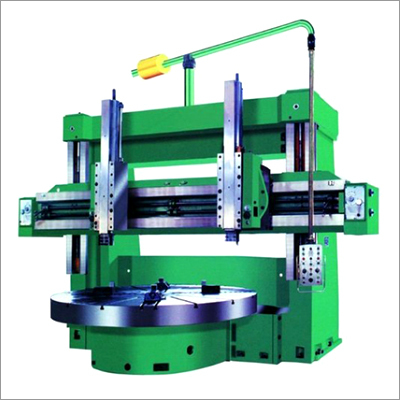

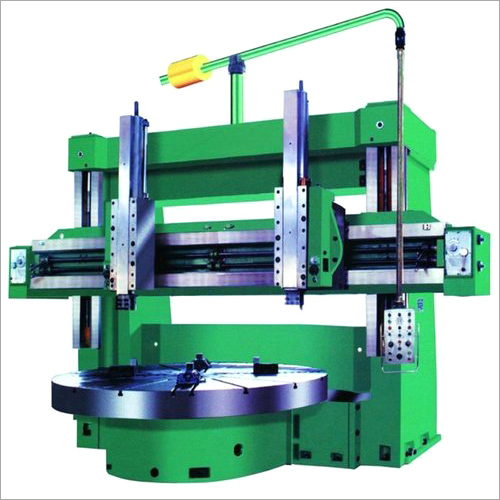

Vertical Turning Lathe Machines

Vertical Turning Lathe Machines Specification

- Product Type

- Vertical Turning Lathe Machine

- Material

- Cast Iron, Alloy Steel

- Cutting Thickness

- Up to 300 mm

- Cutting Speed

- 10 - 400 mm/min

- Engraving Area

- 500 mm to 3000 mm (Swing Diameter Range)

- CNC Or Not

- Optional (Available in CNC & Conventional)

- Automatic Grade

- Semi-Automatic / Automatic

- Control System

- Manual / CNC Controller

- Max. Swing Diameter

- 3200 mm

- Voltage

- 380 V / 415 V

- Weight (kg)

- 15000 kg Approx.

- Dimension (L*W*H)

- 3000 x 2200 x 3400 mm

- Capacity

- Heavy Duty Turning

- Feature

- Robust Structure, High Precision, Rigid Construction

- Color

- Sky Blue / Custom

- Tool Turret

- Manual / Automatic

- Coolant System

- Yes

- Application

- Heavy Duty Turning, Boring, Grooving, Facing

- Spindle Speed Range

- 5 - 160 rpm

- Work Table Load Capacity

- 8000 kg

- Maximum Turning Height

- 1600 mm

- Table Diameter

- 2000 mm

- Power Source

- Electric

- Lubrication System

- Centralized Automatic

- Hydraulic System

- Included

- Main Motor Power

- 22 kW

- Number of Tool Posts

- 2

Vertical Turning Lathe Machines Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Vertical Turning Lathe Machines

We are supplying a wide assortment of the Vertical Turning Lathe Machines, which are popularly known among our customers owing to their superior design and quality. These machines are capable of standing rust, shear forces, and impacts. Due to longevity and high operational reliability, the demand for the lathe machine is very high in the marketplace. To cater to the diverse demands of our customers, we are supplying Vertical Turning Lathe Machines in a plethora of sizes and types. Our customers can get the lathe machines from us at a cost-effective price.

Specification

| Particulars | UNIT | VT-1.0 | VT-1.2 | VT-1.5 | VT-2 | VT-2.5 | VT-3 | VT-4 | VT-5 | VT-6 |

| Table Diameter Max. Turning Dia with | mm | 1000 | 1200 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 |

| Side head below the table top | mm | 1260 | 1600 | 1750 | 2250 | 2750 | 3500 | 4500 | 5500 | 6500 |

| Max. Turning Dia with Side head in working position | mm | 1100 | 1500 | 1700 | 2500 | 2800 | 3500 | 4500 | 5500 | 6500 |

| Max. working height under cross rail | mm | 1000 | 1200 | 1200 | 1700 | 1700 | 2200 | 2200 | 2500 | 2500 |

Heavy-Duty Performance

Designed for industrial and manufacturing environments, this vertical turning lathe can accommodate workpieces up to 8000 kg and supports cutting thicknesses up to 300 mm. Its 22 kW motor ensures powerful, stable cutting even for challenging materials.

Versatile Machining Capabilities

With manual and automatic tool turret options, a swing diameter range from 500 mm to 3200 mm, and both CNC and conventional configuration available, this VTL adapts to a variety of heavy turning, boring, and facing tasks.

Precision and Automation Features

Benefit from centralized automatic lubrication, integrated hydraulic and coolant systems, and optional CNC control for high accuracy, reduced maintenance, and enhanced operational efficiency, making it suitable for continuous production lines.

FAQ's of Vertical Turning Lathe Machines:

Q: How does the vertical turning lathe accommodate heavy workpieces?

A: The machine is built with a robust structure and an 8000 kg worktable load capacity, allowing it to securely hold and machine large and heavy components, making it suitable for applications in sectors like aerospace, energy, and heavy machinery manufacturing.Q: What are the main applications for this 2000 mm table diameter VTL?

A: This lathe is ideal for heavy-duty turning, boring, grooving, and facing operations on large cast iron or alloy steel parts, commonly used in the fabrication of valves, wheels, flanges, and various industrial components.Q: When should I choose CNC versus conventional operation mode?

A: Select the CNC option for jobs requiring precision, automation, and repeatability, particularly in mass production settings. The conventional mode is preferable for custom or low-volume tasks where manual adjustments are needed.Q: Where can this vertical turning lathe be installed?

A: With a substantial footprint (3000 x 2200 x 3400 mm) and a weight of approximately 15,000 kg, this machine is best suited for installation in industrial workshops or manufacturing facilities with adequate floor space and appropriate electrical supply (380/415 V).Q: What is the process for changing tool turrets on this machine?

A: This VTL supports both manual and automatic tool turret options. Manual turrets can be changed by the operator directly, while automatic turrets are managed via the machine's control system or CNC interface for efficient tool changes during production.Q: How does the centralized automatic lubrication system benefit the user?

A: The centralized automatic lubrication system ensures continuous and consistent delivery of lubricant to vital machine parts, reducing wear, minimizing maintenance intervals, and improving overall machine lifespan and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Turning Lathe Machines Category

VTL Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Color : Blue & White

Material : Cast Iron, Mild Steel

Automatic Grade : Other, SemiAutomatic / Automatic

Feature : Other, Heavy Duty, High Precision, Rigid Construction

Vertical Turning Lathe Boring Machine

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Color : Industrial Grey/Blue

Material : Cast Iron, Steel, Alloy Steel

Automatic Grade : Other, Semiautomatic / Automatic

Feature : Other, Robust Structure, High Precision, Smooth Operation

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free